This past summer, Rivertown Solar encountered its most challenging roof to date, a curved, triple-barrelled EPDM roof, made of 2 1/4" decking material covered with 2" of extruded polystyrene insullation.

The great challenge of the roof wasn't this unusual material or even the shape of the roof itself, but creating a racking system, entirely custom, that supported itself between 16 foot long spans.

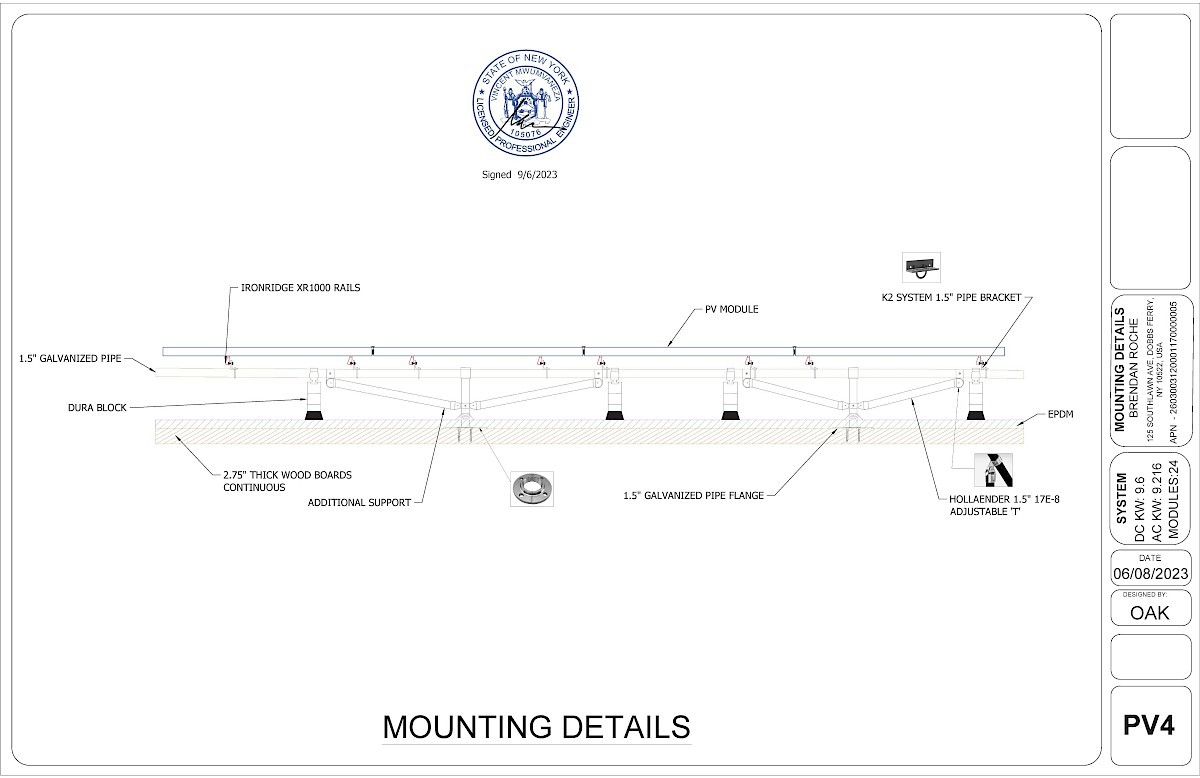

So we built our own custom solar racking system from 1.5" galvanized steel pipe. We choose galvanized steel pipe because it is thick, durable, long-lasting, and weather resistant. To further strengthen the structure, we sistered the horizontal pipe with a diagonal one extending from the base of our attachement point.

In order to adhere to the snow and wind load requirements, this custom structure must be engineered in such a way as to be able to support that dead load; and the structure must be capable of withstanding maximum wind and snow loads for the area, which, for NYS, are 115 mph and 30 mph, respectively.

Another challenge was to locate and attach to the structural beams. Locating them was especially difficult, as we could not see or easily feel our way through the insulation membrane. And so we had to measure precisely using a laser distance measurer.

We used a hole saw bit to cut a 4in hole through the membrane up to the TJI beam. We then tied into the beam using four 6" lag screws and a galvanized pipe flange. We then filled the cavity around the anchor point with fire-rated foam. At the point of the level with the roof plane, we added an EPDM pipe boot that was then sealed with a Firestone compatible lap sealant. We also added non-penetrating attachement blocks in between the long span pipe for added support.

Finally, on top of the galvanized steel structure, we laid Ironridge XR1000s, to which we attached our inverters (APSystems DSL-3) and our modules (Hanwha Q Cell 400w).

The resulting 9.6 kW system is expected to produce 9,611 kwh annually.